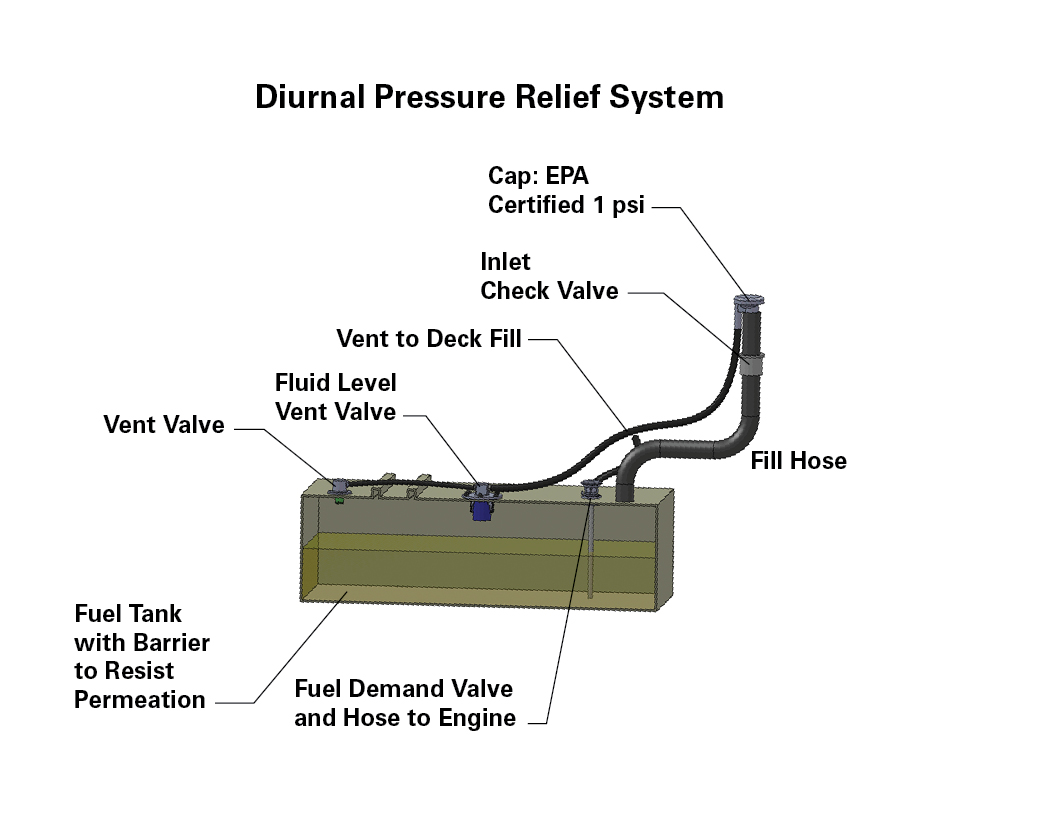

Pressure System

A pressure system is a closed system in which the inside fuel system and all of its components are sealed. Fuel and vapor in the system interact with the outside in two situations:

- 1. During a filling event when the fuel cap is removed and the fill hose and vent are opened to the outside

- 2. When the pressure in the tank rises above 1 psig and the fuel cap “breaks” and vents to the outside. This may be a fuel cap on a direct fill or on the deck fill component. After the system vents, the cap re-seals and is ready to work again at 1 psig.

At all other times, the tank, fuel, and pressure within the system is controlled by cap valving. Most of the time, the pressure in the system cycles between 0 to 1 psig and no vapor escapes the system because it does not vent out. On the occasion that the pressure exceeds the cap rating, it will vent off.

Advantages of the pressure relief system:

- It ordinarily requires fewer parts than the carbon canister system.

- There is no need to purchase a carbon canister.

- Contamination by water or fuel is a non-issue.

- No venting is required through the hull of the boat and to a P-trap. Fill is usually more dependable because it’s possible to plumb the fluid level valve to the deck fill, which eliminates the flow restriction of canister systems.

Disadvantages:

- Fuel is under pressure up to 1 psi.

- Extra labels are required at fill of tank to notify the user of possible pressure in the tank when the cap is removed.

- Fuel pressure attenuation valve to the carburetor or injection unit is required.

- If using a deck fill, the fill might require that a 5/8” fitting be used to connect with the hose from the FLVV to it, which adds cost.