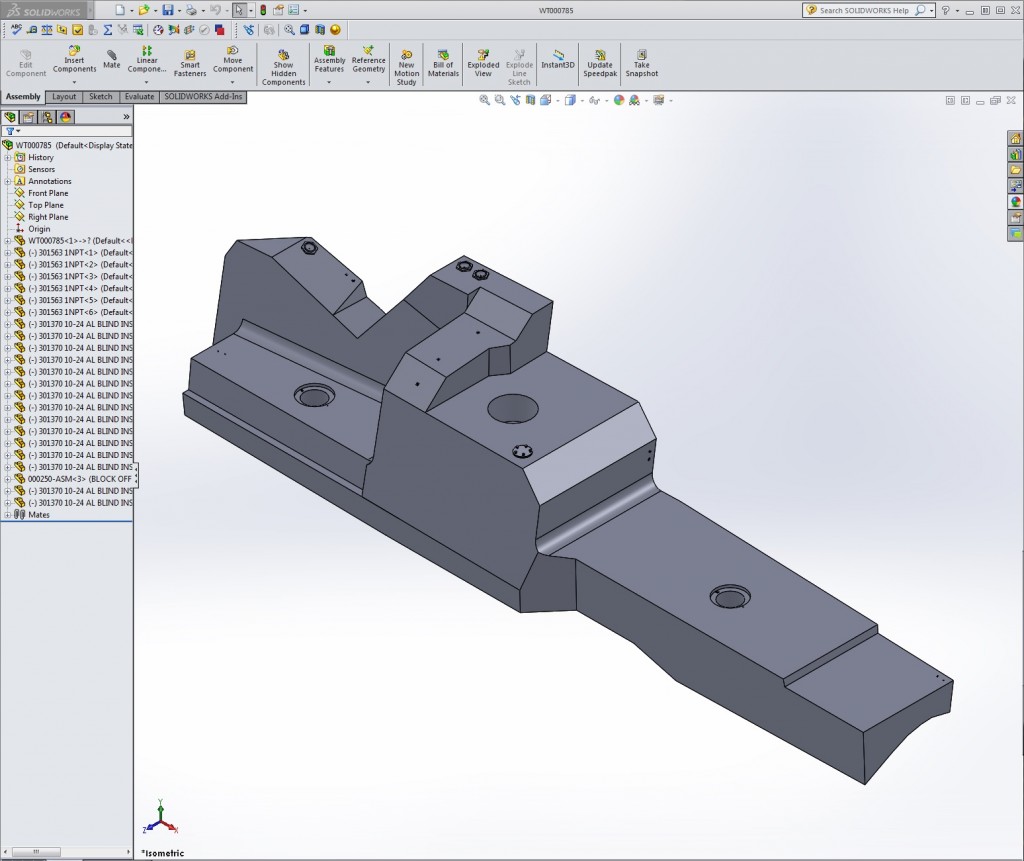

Custom Tank Design

Custom projects begin with a discussion between the customer and Moeller engineering staff to identify design parameters and performance requirements. From this point, the Moeller team reviews the scope of the project, develops initial concepts, generates a design proposal, and builds a prototype. The process is summarized below. For a detailed description of the design process, click below.

![]()

The purpose of the Review is to define requirements, identify essential data, and determine feasibility.

The Team gathers additional information, reviews it with the customer (as necessary), and develops a preliminary engineering proposal.

The Final Proposal ordinarily includes detailed prints, specifications, and firm pricing on both the product and the tooling.

Once the customer has approved the proposal, Moeller builds the tooling, then produces—and tests– a prototype. The final step is submitting the prototype to the customer for approval.

Most projects take from six-to-eight weeks from review through prototype development. A rush project, including tooling fabrication and prototyping, may take as little as two-to-three weeks, if there are no holdups for approvals.

To get your quote started on a custom aluminum tank use our custom aluminum tank quote builder.